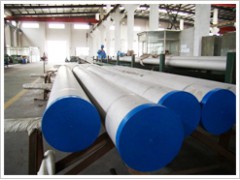

High-quality Seamless Stainless Steel Pipe in large diameters can help clients to extend the anti-corrosion capability and lifetime of products, which will be more efficient in the project when the material utilized

ASTM A790/ASME SA790 Seamless and welded ferritic/austenitic stainless steel pipe

ASTM A312/ASME SA312 Seamless and welded austenitic stainless steel pipes

ASTM A511/ASME SA511 Seamless stainless steel mechanical tubing

DIN 2448 Seamless steel pipes and tubes

DIN 6258 Hollow steel bars for machining

GOST 8731 Seamless hot rolled steel pipes - technical requirements

JIS G3459 Stainless steel pipes

1.100% pmi / spectro chemical analysis tests

2.100% dimension tests & 100% visual examination

3.tension test, flaring tests(for seamless tube/pipe)/flange tests(for welded tube/pipe), hardness test, reversed flattening test(for welded tube/pipe), flattening test (for seamless tube/pipe)

4.100% hydrostatic test/100% non-destructive tests

notes : all the tests and inspection need to provide with reports according to standard and test results

Option Test & Inspection Items

1.straightness test

2.roughness test

3.crystalling phase analysi

4.intergranular attack tests

5.impact attack test under low temperature

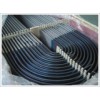

6 .u-bend balling pass test u

7.pt test on bending area

8.ultro-sonic testing

The DocumentsLSI Will Provide to You

a.mtc (material test certification) according to en10204/3.1 or en 10204/3.2

b.raw material certification

c.all the test & inspection reports as per po and standards

d.heat treatment report

e.shipping notification before shipment

f.quality warranty letter