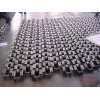

This production line is used for Aluminium & Aluminium alloy conductor(magaluma, Almasilium etc. ), by adopting continuous casting and rolling technology, with output rod of diameter 9.5mm. It consists of of melting furnace, holding furnace, casting machine, oil shearer, rolling mill and coiling system. Aluminium Alloy Rod Continuous Casting and Rolling Line Type UL+Z-1500+255/14 Melting furnace Shaft furnace 5t/h Melting rate Holding furnace Hydraulic tilting-type 2×9t Capacity (ton) Filter & degassing device Treatment gas Nitrogen or Argon Treatment capacity (kg/min) 30~100 Degassing efficiency (%) 50~70 Container capacity (kg) 440 Casting machine Casting ring dia. (mm) 1500 Casting bar speed (m/min) 8~12 Casting bar section (mm²) 2300 Water consumption (m³/h) 100 Motor for casting ring (kw) 4 Accessory shearer Max. shearing force (kg) 14000 Max. shearing stroke (mm) 85 Straightening & edge shaver No. of straightening roller 5 Pulling motor (kw) 3 Induction heater Output frequency (Hz) 350 Output power (kw) 300 Water consumption (m³/h) 15 Rolling mill Outlet rod dia. (mm) 9.5 No. of rolling stand (m/s) 14 Rollers' dia. (mm) 255 Finished rolling speed (m/s) 4-6 Production capacity (ton/hour) 2.6~4.0 Center height (mm)Main motor (kw)Emulsion consumption (m³/h) 1052.5355(DC)60 Rod quenching device Rod quenching tunnel 8 Outlet rod temperature (ºC) ≤100 Water consumption (m³/h) 60 Rod orbital coiler Pulling speed (m/s) 6.94 Pulling motor (kw) 7.5 Coil's size (mm) Φ1500×2300 Laying head motor (kw) 4 Coils' weight (kg) 1500~1800