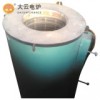

Application: This cyclic working furnace is high temperature well type resitance one for the normalizing, annealing, and quenching treatment of alloy steel, high speed steel, high-manganese steel, high-chrome steel, bearing, pipes and mechanical parts. Work Temperature: 1200 degree celsius Power: 15-4900KW Furnace diameter: Dia 300mm-11m Largest Depth: 50m Features: The shell of the furnace is a column of steel plates and section steel by airproof welding. The furnace lining is made of super light 0.6g/cm3 energy saving vacuum balls and refratory heat preserving bricks. The interlayer between the lining and the furnace shell is silicate aluminum fiber felt for preserving the heat with remaining space filled with heat-preserving expansion powder. The 0Cr27Al7Mo2 resistance wires are coiled into the sprial shape installed on the wire supporting bricks. The furnace cover is lifted up and down manually or electrically. If the buyer wants to treat the metal workpieces under a protective atmosphere, three stainless steel oil fillers are to be installed with the furnace cover in order to produce a simple protection atmosphere. At the lower part of the furnace hearth are nitrogen inlet pipes which let through nitrogen or disperse combustible gases preventing explosion accidents. One limit switch is set up for the lifting mechanism, which is interlocked with the control cabinet. When the furnace cover is sealed with the furnace body, the electricity is swithced on. When the furnace cover opens, the limit switch would intercept the control power, which intercepts the power for the heating components too. The automatic temperature control cabinet and thermal couplings are provided working along the furnace. To meet different requirements, we offer tailor-made service to our customer.