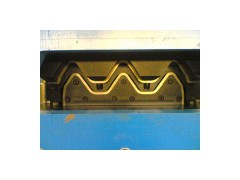

cold forming, cold punching, automatic stack, industrial automatic control system and precision machining technology, which make the full working flow goes full automatically with high efficiency. It can produce 600tons(max. ) finished guard rails per month on the base of one shift everyday. The full production line consists of decoiling system, leveling system, edge cutting system, head cutting system, punching system, roll forming system, post cutting system, automatic stacking system, hydraulic system and automatic control system. Technical paramete: 1: Suitable material of type: Galvanized steel sheet/hot rolled steel coil(depend on customer's requirements and final design) Suitable of thickness (mm): 3.0-4.0mm (depend on customer's requirements and final design) Suitable of yield Strength (Mpa): 235Mpa (depend on customer's requirements and final design) Suitable of coil Width (mm): 482/748mm 482mm/W Beam, 748mm/Thrice Beam 2. Forming Speed (m/min): Variable 20-25m/min Excluding cutting and punching time 3. Total power: 87KW (depend on final design) 4. Power: AC380V, 50Hz, 3 Phase (depend on customer's requirements and final design) 5. Dimension (L× W× H, m): 23× 7× 1.5 (depend on final design and actual) 6. Roller Material: D2 Steel Mould Steel 7. Shaft Material: 45# Steel 8. Total Weight: 55 Ton (depend on final design and actual)