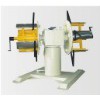

High Speed Roller Feeder Structurer Features: 1. Single-Direction Bearing (made in Germany) Inlayed cemented carbide alloy which coordinates with roller bearing, featuring good abrasive resistance, safety, high accuracy And long service time. Gears are processed through heating treatment HRC600 and then through high accurate grinding. Hence high driving accuracy. 2. Roller Processed through heating treatment HRC600 and then through grinding; Hollow structure, light in weight, weak gyration inertia, casual stop, and with high feeding accuracy; Featuring high hardness, good abrasive resistance and long service span. 3. Disk Type Brake (common brake device) Adopted high-quality clutch disk lining whose two faces interconnected completely, featuring long service span, good stability, and high accuracy. 4. Reversing Device: (1) The structure is the same as that of single-way device. It controls the lower gear with high accuracy and can maintain the lower wheel a long-time stability and high accuracy. (2) The problem of the overturning of the lower wheel caused by sprayed oil when pressed is avoided. (3) Not apt to cause high heat. (4) With cemented carbide alloy and roller bearing, free of abrasion. (5) That the roller bearing works in a circular motion way can avoid bearing seizure. (6) It has weak frictional force and needs low torque fore. Its rotating drive is not apt to be damaged. (7) The reversal device's speed can reach to 30m/min, increasing 50% compared with common speed of 20m/min. (8) Special structure is adopted to extend its service span. Advantage of roller feeder 1. Durative: Many project continuous processing is available. 2. High Speed: Can reach 600 times per minute 3. Fargoing using: For different width and thickness material, only need to adjust feeder to match mold. 4. Compact structurer, economical using 5. Low malfunction, easy maintenance Feeding precision: Depend on revolution and feeding length, normal accuracy is 0.03mm, if guide pin is located, accuracy can reach 0.01mm Format: Single style: Suitable for coil(thickness is above 0.15mm), single manufacturing product or continuous pressing products. Double style: Suitable for coli(thickness is under 0.15mm), short inch material, single manufacturing product continuous pressing.Model Roller width (mm) Feeding length (mm) Material thickness (mm) Material thickness Press capacity Size Weight A B C D E F G M LH-105NS 100 50 0-1.6 55-100 5-20 537 247 250 292 200 95 295 120 64 LH-205NS 200 50 0-1.6 55-100 20 637 347 270 342 220 125 345 120 87 LH-255NS 250 50 0-1.6 55-100 20 687 397 270 367 220 125 345 120 95 LH-305NS 300 50 0-1.6 55-100 40 737 447 270 392 220 125 345 120 103 LH-355NS 350 50 0-1.6 55-100 40 787 497 270 417 220 125 345 120 111 LH-405NS 400 50 0-1.6 55-100 60 837 547 270 442 220 125 345 120 121 LH-455NS 450 50 0-1.6 55-100 80 887 597 270 467 220 125 345 120 101 LH-505NS 500 50 0-1.6 55-100 80 937 647 310 492 220 125 345 120 141