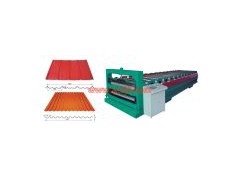

Standard Double Deck Forming Machine, YX840-850, corrugation and trapozoidal Specialized in the filed of roll forming machine since 1998, with 12 years' experience. Manufacture both standard and customized, , as per their specific needs and requirements.1. General This Double Deck Forming Machine can separately produce corrugation roof and trapezoidal roof in one machine. You can also choose other 2 profiles to produce in the double layer forming machine. Automatically cut to length, PLC control, and Frequency Converter.This line consists of 5-Ton Mechanical uncoiler, guiding and feeding device, DUAL LEVEL roll former, run out table, PLC controller, hydraulic post-cutting equipment, electrical control system, hydraulic system, etc. 2. Producing Process Sketch decoiling the sheet-sheet guiding -roll forming-measure length -cutting the panel-panels to the supporter 3. Technical Parameters 3.1 main machine NO Item Parameters 3.11 suitable material Pre-Painted or Galvanized Steel Sheet, Yield Strength (Mpa) 235Mpa, 0.25-0.8mm thickness, 1000, 1200 or 1250 width. 3.12 Forming Speed 10-12m/min 3.13 Power AC380V, 50Hz, 3 Phase(adjustable) 3.14 Main Motor Power 4kw 3.15 Hydraulic Power 3kw 3.16 Dimension (L*W*H) 6.8*1.3*1.5m 3.2 components 3.21 Roller Material 45# steel, hard chrome plating. Thickness of chroming: 0.05mm 3.22 outer diameter of shaft Φ 75mm 3.23 Cutting blade Cr12 mould steel with quenched treatment. 3.24 brand PLC MITSUBISHI Products Warranty: One year. We will provide the technical support for the whole life of the equipment